2023/24 VC owners thread general discussion

- Thread starter Woodsplitter67

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I am interested in that conversation @VCnewbe, did you start a new thread?

yes a new thread was started

arnermd

Minister of Fire

I was just looking at my refractory this morning (just to make sure all was well) and I came to the same realization. I agree, that's the answer.... need a plate there to keep the molded air passages clear.So the refractory engine has the molded secondary air passages in it.. I believe that the SS gasket is the plate that helps keep the air metered correctly. Whith out it I think the gasket would settle into the secondary air holes and reduce the amount of air getting into the catalyst chamber for combustion.. What are your thoughts

AsylumResident

Feeling the Heat

I have the Defiant Model 1975-CAT-C as listed in my manual. @arnermd you have yours listed as the Defiant 2n1 model 1975. I know you purchased your stove years ago and as I read through the 2022/2023 thread I see the challenges you have had and how you've had to rebuild yours twice now I believe. I purchased mine in early 2023. Are our stoves the same, or do we know if they have made changes on more recent models?

arnermd

Minister of Fire

That's a very good question.... I do not know if there are differences or not. I suspect if any they are minor, but honestly I do not know. Would be interested to hear if anybody knows....

Now that I think about it.... a couple years back I compared part numbers (my stove vs the Cat-C) and I think almost all of them were identical.... Can't recall which ones were different. However what I do not know is if they changed the design and kept the same part number.

Yes I purchased many years ago.... Jan 2012, on my third refractory set and 5th cat....(#5 is a metal cat)

When it burns right I love this stove, when the cat temps run off I hate it.....

I can not definitively say that I have an explanation or a fix for runaway cat temps.... I have tried a lot of things, some make things incrementally better but not 100%. My latest mod was adding restriction to my key damper in the exhaust duct to reduce draft, seems to be helping but again not 100%......

With these occasional burns in shoulder months it is a struggle to get cat temps up over 900. Earlier this week I had cat temps up to 1200 (100% air, gridle at 600) throttled the air way back (10% open) and over a period of 1-2 hours cat temps dropped to 500.... plenty of wood in the firebox. I suspect the cause is draft too low due to warm air outside, my additional restriction and I need to clean my flue.....

I am very interested to see what your experience is when you get cranking this winter. Take a look at the parts diagrams and see if you can figure out which parts are different. Maybe we can share pics and measurements to figure it out....

Now that I think about it.... a couple years back I compared part numbers (my stove vs the Cat-C) and I think almost all of them were identical.... Can't recall which ones were different. However what I do not know is if they changed the design and kept the same part number.

Yes I purchased many years ago.... Jan 2012, on my third refractory set and 5th cat....(#5 is a metal cat)

When it burns right I love this stove, when the cat temps run off I hate it.....

I can not definitively say that I have an explanation or a fix for runaway cat temps.... I have tried a lot of things, some make things incrementally better but not 100%. My latest mod was adding restriction to my key damper in the exhaust duct to reduce draft, seems to be helping but again not 100%......

With these occasional burns in shoulder months it is a struggle to get cat temps up over 900. Earlier this week I had cat temps up to 1200 (100% air, gridle at 600) throttled the air way back (10% open) and over a period of 1-2 hours cat temps dropped to 500.... plenty of wood in the firebox. I suspect the cause is draft too low due to warm air outside, my additional restriction and I need to clean my flue.....

I am very interested to see what your experience is when you get cranking this winter. Take a look at the parts diagrams and see if you can figure out which parts are different. Maybe we can share pics and measurements to figure it out....

AsylumResident

Feeling the Heat

I plan to be pretty active on here as the burning season picks up. Regardless of the personality of my stove I'm committed to making it work. I am very interested to see how mine operates compared to yours (based on your season last year) better or worse and then try to determine if it is a mechanical difference (potential design or parts change over 10 years) or if it's something else. I understand all set ups are different and I'm not expecting the same results between the stoves but I am interested in finding similar themes so to speak.

Right now I am running the auber for the Cat temps and will be getting another one for the flue temps. I also have a magnetic STT. If I do end up with consistent run away Cat temps I will most likely look into a set up similar to yours so I can have real time data to make adjustments. I understand more information and data can be a double edged sword but I'm much more inclined to have that data than not.

My current set up is a basement install. I have the stove pipe come off the stove about 30" to an elbow then out through the basement block wall. From there it goes up 16' on the outside of the house, through the soffit and roof. This year the outside pipe will be exposed all winter. I plan to build around it next summer. Everything from stove to cap is 6" DW. I will be running shorter and smaller than your chimney plus having most of the chimney exposed to the elements. It will be interesting to see how the winter goes.

Right now I am running the auber for the Cat temps and will be getting another one for the flue temps. I also have a magnetic STT. If I do end up with consistent run away Cat temps I will most likely look into a set up similar to yours so I can have real time data to make adjustments. I understand more information and data can be a double edged sword but I'm much more inclined to have that data than not.

My current set up is a basement install. I have the stove pipe come off the stove about 30" to an elbow then out through the basement block wall. From there it goes up 16' on the outside of the house, through the soffit and roof. This year the outside pipe will be exposed all winter. I plan to build around it next summer. Everything from stove to cap is 6" DW. I will be running shorter and smaller than your chimney plus having most of the chimney exposed to the elements. It will be interesting to see how the winter goes.

AsylumResident

Feeling the Heat

Temperatures dropped today and will be lower all week. Just got the stove fired back up.

View attachment 317490

Thats a really good looking Jotul there.. Im guessing thats the F500 V3

JohnDaileyNH

Feeling the Heat

It's 80 here. No burning this weekend. Only golfTemperatures dropped today and will be lower all week. Just got the stove fired back up.

View attachment 317490

AsylumResident

Feeling the Heat

I would be ok getting another round of golf in this year yet.It's 80 here. No burning this weekend. Only golf

AsylumResident

Feeling the Heat

...I'm no expert.Thats a really good looking Jotul there.. Im guessing thats the F500 V3

...I'm no expert.

Waiting for someone to say.. WTF.. its not a Jotul..

U235

Member

As requested:Do the transformation post!

Converting an open hearth to stove in (combustible) alcove

I had some trouble finding examples of people who had done this conversion. I don’t claim to know the codes where you live - I shared my plans with my local town inspector, got permits, and scheduled inspections at the requested intervals. For me, this was relatively cheap insurance in case I...

www.hearth.com

www.hearth.com

VCnewbe

New Member

I thought it if that countsWaiting for someone to say.. WTF.. its not a Jotul..

Reckless

Feeling the Heat

Nice to see some familiar names! Still running my VC this year, scared to look at the cat bc I really don’t want to buy a new one 😂 hope everyone is doing well!!

Nice to see some familiar names! Still running my VC this year, scared to look at the cat bc I really don’t want to buy a new one 😂 hope everyone is doing well!!

What VC stove do you gave.. I forget.

At the risk of sounding like a know it all (I'm not) I think the VC stoves with the catalyst was a bit of design flaw due to compromise. With the epa cracking down on wood fueled heat, VC had to do something to stay alive.

I can't imagine they were willing to completely redesign thier engineering to satisfy the newer requirements.

A bottom draft stove worked for years and is every bit of a 50nyear old design. I feel adding the catalyst at the bottom when the damper is engauged may not have been ideal. This requires a strong upward draft to pull the gasses through the cat as apposed to the natural flow of heat rising upward. With strong drafts comes the need for strong air inlet controls. These stoves are passive air pumps. They use temperature differentials to work. Adding a secondary heat source to the bottom and rear (the cat area) means you now have two engines running inside one machine. The primary heat box being one, and the catalyst being the other.

How do these stoves control the heat being generated why two different engines and one air inlet source?

I believe having a dynamic air inlet and exhaust control working together is the only way this can work without human intervention.

I can't imagine they were willing to completely redesign thier engineering to satisfy the newer requirements.

A bottom draft stove worked for years and is every bit of a 50nyear old design. I feel adding the catalyst at the bottom when the damper is engauged may not have been ideal. This requires a strong upward draft to pull the gasses through the cat as apposed to the natural flow of heat rising upward. With strong drafts comes the need for strong air inlet controls. These stoves are passive air pumps. They use temperature differentials to work. Adding a secondary heat source to the bottom and rear (the cat area) means you now have two engines running inside one machine. The primary heat box being one, and the catalyst being the other.

How do these stoves control the heat being generated why two different engines and one air inlet source?

I believe having a dynamic air inlet and exhaust control working together is the only way this can work without human intervention.

arnermd

Minister of Fire

I tend to agree with you although I am not familiar with the Dauntless. For my stove (Defiant model 1975) my biggest concern is the lack of secondary air control and the mixing of secondary air to support primary combustion. I think it requires a delicate balance of conditions.

That being said many folks have had great success with reliable consistent burns..... I have been on a 3 year quest to understand why my stove / setup seems to be particularly vulnerable to cat over fires. No definitive answers yet.

That being said many folks have had great success with reliable consistent burns..... I have been on a 3 year quest to understand why my stove / setup seems to be particularly vulnerable to cat over fires. No definitive answers yet.

Interesting about your Defiant's secondary air control.I tend to agree with you although I am not familiar with the Dauntless. For my stove (Defiant model 1975) my biggest concern is the lack of secondary air control and the mixing of secondary air to support primary combustion. I think it requires a delicate balance of conditions.

That being said many folks have had great success with reliable consistent burns..... I have been on a 3 year quest to understand why my stove / setup seems to be particularly vulnerable to cat over fires. No definitive answers yet.

To my knowledge, my Dauntless only has a primary air control inlet and does not auto adjust the metering of air when running in crusie Bypass engauged mode.

Interesting about your Defiant's secondary air control.

To my knowledge, my Dauntless only has a primary air control inlet and does not auto adjust the metering of air when running in crusie Bypass engauged mode.

So the bimetal air control does meter the primary air to a degree.. there is a secondary air inlet that is used to feed the refractory and refractory engine that has no air control.. Im assuming is mostly draft driven

My Duantless doesnt have a bi-metal flap controller. The air control lever on the right side controls a flap on the lowest rear part of the stove (where the external fresh air pipe mount goes). That's it.So the bimetal air control does meter the primary air to a degree.. there is a secondary air inlet that is used to feed the refractory and refractory engine that has no air control.. Im assuming is mostly draft driven

If these stoves used to come with a bi-metal thermastatic control, it was removed in production in my version.

My Duantless doesnt have a bi-metal flap controller. The air control lever on the right side controls a flap on the lowest rear part of the stove (where the external fresh air pipe mount goes). That's it.

If these stoves used to come with a bi-metal thermastatic control, it was removed in production in my version.

So your stove does have a thermostat.. it may not be bimetal.. force of habit typing it.. your thermostat is on the inside of the stove. In your stove you also have an air control assembly.. as the other stoves.. My stove has a flapper.. yours might have something a little different.. I haven't taken you stove apart and Im not an expert.. but I know your stove has these..

My Duantless doesnt have a bi-metal flap controller. The air control lever on the right side controls a flap on the lowest rear part of the stove (where the external fresh air pipe mount goes). That's it.

If these stoves used to come with a bi-metal thermastatic control, it was removed in production in my version.

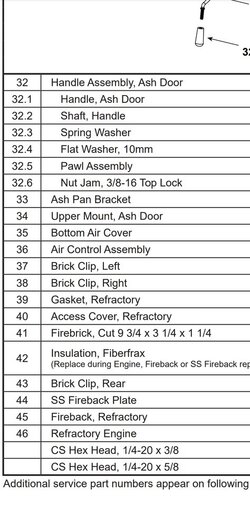

So I looked up your stove... Your thermostat is in the air manifold. The drawings aren't the best.. but you have a cable that goes to your air assembly that controls that amount of air the stove receives.. Here is your parts list

your looking at #36 and 49 to 52

You probably do have a flapper.. behind the cover

GrumpyDad

Minister of Fire

Have you tried burning without the CAT? I have my stove somewhat dialed in but not always. I was concerned with destroying my cat, and relegated it to my lower burns when I did see the value of doing so. But removed as I left shoulder season but tried from time to time to determine if it better for overnight burns. This is a controversial subject.I tend to agree with you although I am not familiar with the Dauntless. For my stove (Defiant model 1975) my biggest concern is the lack of secondary air control and the mixing of secondary air to support primary combustion. I think it requires a delicate balance of conditions.

That being said many folks have had great success with reliable consistent burns..... I have been on a 3 year quest to understand why my stove / setup seems to be particularly vulnerable to cat over fires. No definitive answers yet.

but I can only go by my experience. I inquired with two stores about this, one is a well known dedicated shop that carries a wide variety of stoves and another sells stoves as a means to an end on top of all the other stuff they sell. Both seemed to suggest you would leave the cat in all season. But when I would show them the brochure from VC's website that shows efficiency goes down as you burn hotter, there was no explanation. VC didnt reply. I dont think this will change the temperatures much in your secondary, but maybe it will as those gases arent being combusted as easily. I do not get the jet blast sounds that others get, but I do recall once getting it with the cat installed during a hotter fire. So who knows, give it a shot.

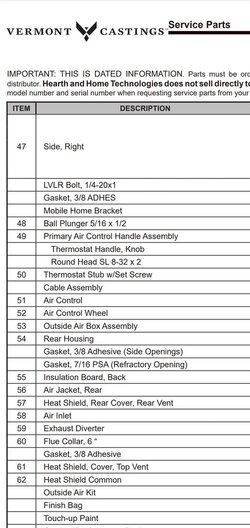

but I can only go by my experience. I inquired with two stores about this, one is a well known dedicated shop that carries a wide variety of stoves and another sells stoves as a means to an end on top of all the other stuff they sell. Both seemed to suggest you would leave the cat in all season. But when I would show them the brochure from VC's website that shows efficiency goes down as you burn hotter, there was no explanation. VC didnt reply. I dont think this will change the temperatures much in your secondary, but maybe it will as those gases arent being combusted as easily. I do not get the jet blast sounds that others get, but I do recall once getting it with the cat installed during a hotter fire. So who knows, give it a shot. Below is the screenshot from VC's website that shows efficiency actually goes down as the stove burns hotter. Sorry the imagine stinks, but this is what they have on their website. Notice that anything beyond a minimal burn and you are just wasting the use of a catalyst if efficiency is anything you care about, which for me it is one of the most important things, only second to safety. I did not notice much less smoke with the cat installed once I had a warm stove. What's interesting is, there is no mention of what a minimum burn would be. Because there is a minimum to which the cat actually operates. And once you are there, your stove is burning pretty hot. So to me, that would mean the window for using the cat is so minimal unless you get it to operate catalyst range, and work to keep it there.

Similar threads

- Replies

- 700

- Views

- 30K

- Replies

- 78

- Views

- 11K

- Replies

- 14

- Views

- 5K

- Replies

- 3

- Views

- 2K

- Replies

- 0

- Views

- 7K