My father has a PE Alderlea T5 that he likes. It looks good and throw heat nicely too. Its a big reason why I got my woodstove this year.

He has a tall probably 20-25' class A chimney going straight up.

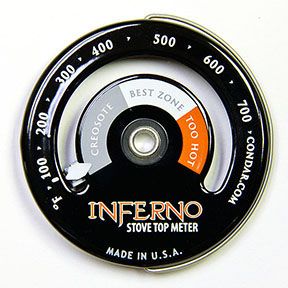

Anyways, the stove always runs super hot, so I got him a Condar stove top thermometer for Christmas.

This one:

http://www.condar.com/Stovetop_Thermometers.html

It seems that if you put more than 2-3 splits in there it pins the needle on the TOO HOT scale. Even if you try and catch it on the way up and set to low very early it just keeps climbing. He says he found the top of the stove glowing before. The place were he got the stove, has told him it's impossible to overfire a PE stove and not to worry about it. I'm a little concerned... should I be? or is the biggest problem that he basically just wasting wood by sending all that heat up the chimney?

For the first two years he was trying to run the stove with a magnetic surface thermometer stuck to his stove pipe, but it's double wall the "clean" zone indicated on the thermometer is likely way too hot for double wall.

Should I suggest he get a damper to control the draft better and bring the stove top temps down a bit?

Upside, his glass is way cleaner than my BK glass with 800-900F stove top temps.

He has a tall probably 20-25' class A chimney going straight up.

Anyways, the stove always runs super hot, so I got him a Condar stove top thermometer for Christmas.

This one:

http://www.condar.com/Stovetop_Thermometers.html

It seems that if you put more than 2-3 splits in there it pins the needle on the TOO HOT scale. Even if you try and catch it on the way up and set to low very early it just keeps climbing. He says he found the top of the stove glowing before. The place were he got the stove, has told him it's impossible to overfire a PE stove and not to worry about it. I'm a little concerned... should I be? or is the biggest problem that he basically just wasting wood by sending all that heat up the chimney?

For the first two years he was trying to run the stove with a magnetic surface thermometer stuck to his stove pipe, but it's double wall the "clean" zone indicated on the thermometer is likely way too hot for double wall.

Should I suggest he get a damper to control the draft better and bring the stove top temps down a bit?

Upside, his glass is way cleaner than my BK glass with 800-900F stove top temps.

Funny post. I have nothing more to add, except I will add that I have nothing to add (from an old Mash program). But I just saw too much of myself there to not to say something. I'm doing a balancing act like that often. I try to work at it, but this forum just makes it too easy to overspill one's mouth sometimes...

Funny post. I have nothing more to add, except I will add that I have nothing to add (from an old Mash program). But I just saw too much of myself there to not to say something. I'm doing a balancing act like that often. I try to work at it, but this forum just makes it too easy to overspill one's mouth sometimes...