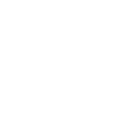

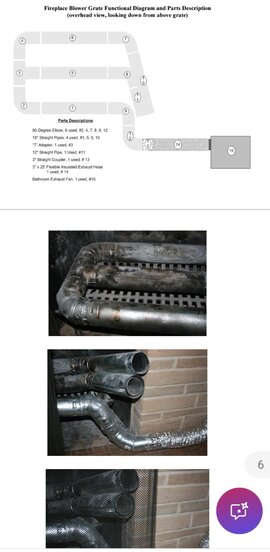

I recently had a cheap DIY fireplace insert created with the assistance of a local muffler shop (total cost = $47 including the fan). They bent a 2.5" diameter ten foot exhaust tube to wind into the back of my fireplace and then back out. I bought an 4" inline duct fan rated at 100 cfm and an adapter to connect them. I know the fan isn't putting out 100 cfm, maybe 50-60% because of the difference in cross sectional area. Regardless, I'm incredibly disappointed at the seemingly minimal effect on heating the room and the temperature of the air coming out of the tube.

Has anyone else created a DIY fireplace heat exchanger that noticeably increased the room temperature? During the day I close the door to the back bedrooms so I'm trying to heat around 800-1000 sqft. My current setup at a temperature of 20-30 degrees outside can maintain the temperature inside once the gas furnace has got the house to a comfortable temperature so it is helpful in keeping the furnace shut off all day, but once the temperature starts dipping in the teens I start going backwards again. It doesn't seem like there is a huge difference between heat output with or without the exchanger.

One of the main things that baffles me is how the fire burns somewhere between 1200-1500 degrees and the environment inside the fireplace where the pipe winds is around 1000 degrees and yet the air coming out of the tube is warm, but not nearly as hot as I was expecting. Something else that surprised me was if I increased the airflow through the tube (reverse hose hook up on shopvac and blew through), the temperature coming out was the same despite seemingly 3-5x more airflow. This suggests to me the the amount of heat output from the pipe is limited by the airflow, at least at the current flow rates. The pipe on the output side, even outside the fireplace is so hot it will burn hand if touched. My main question is why isn't the air coming out hotter. How does the air coming out of a pipe that passes through 1000 environment not burn my hand when I put where the air immediately comes out?

One thought I have is to have several smaller pipes, maybe two inches ran through in the same way and connect to a fan with 200 or more cfm. This would allow more air to be in closer contact with the metal and increase the flow.

I get my wood for free, so yes I know this isn't the most efficient way to heat my house, but even 15% efficiency at zero cost beats 85% efficiency at cost. Also, I'm only going to live here for 3-4 years so it isn't worth putting an insert and chimney liner it since it would never pay for itself, best case scenario i might break even (might as well just crank up the gas thermostat).

Has anyone else created a DIY fireplace heat exchanger that noticeably increased the room temperature? During the day I close the door to the back bedrooms so I'm trying to heat around 800-1000 sqft. My current setup at a temperature of 20-30 degrees outside can maintain the temperature inside once the gas furnace has got the house to a comfortable temperature so it is helpful in keeping the furnace shut off all day, but once the temperature starts dipping in the teens I start going backwards again. It doesn't seem like there is a huge difference between heat output with or without the exchanger.

One of the main things that baffles me is how the fire burns somewhere between 1200-1500 degrees and the environment inside the fireplace where the pipe winds is around 1000 degrees and yet the air coming out of the tube is warm, but not nearly as hot as I was expecting. Something else that surprised me was if I increased the airflow through the tube (reverse hose hook up on shopvac and blew through), the temperature coming out was the same despite seemingly 3-5x more airflow. This suggests to me the the amount of heat output from the pipe is limited by the airflow, at least at the current flow rates. The pipe on the output side, even outside the fireplace is so hot it will burn hand if touched. My main question is why isn't the air coming out hotter. How does the air coming out of a pipe that passes through 1000 environment not burn my hand when I put where the air immediately comes out?

One thought I have is to have several smaller pipes, maybe two inches ran through in the same way and connect to a fan with 200 or more cfm. This would allow more air to be in closer contact with the metal and increase the flow.

I get my wood for free, so yes I know this isn't the most efficient way to heat my house, but even 15% efficiency at zero cost beats 85% efficiency at cost. Also, I'm only going to live here for 3-4 years so it isn't worth putting an insert and chimney liner it since it would never pay for itself, best case scenario i might break even (might as well just crank up the gas thermostat).