After debating the best plan for a woodshed (hashed out in many past threads... ), the decision has been made to keep my 30 cords of CSS’d wood in three long rows of 10 cords each, with aisles wide enough between them to pull the large wagon thru that I use for hauling wood up to the house.

For zoning reasons, these need to be kept as portable structures, so we’re talking about essentially a pallet with a roof to keep the wood dry. This works out, in my case, to be cribs with a footprint of 8’ x 3’. Each will hold a cord of wood, and while technically mobile, they will be bolted together in a long row. There will be approximately 30 of these cribs.

Yes, I know the many potential disadvantages of this plan, but it has several advantages, and I’m willing to accept the trade-off. The question now is on framing.

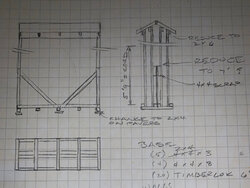

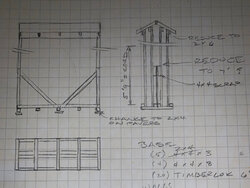

Here is the rough sketch of the design:

Those 2x6 ridge beams, which run 8 feet from side to side at four locations are currently just attached to the four pairs of end wall studs with either four 3” deck screws or two 3” TimberLok fasteners. No jack studs, and I am beginning to wonder if I’ll regret this decision:

(Ignore the 1x2 strapping I’m using for temporary cross-bracing in this photo)

The roof is only 24 square feet, but we sometimes get up to 3 feet of heavy wet snow in a single shot, so snow load could be high. Yet, this thing is already stupid heavy (like 1000 lb.), which is part of my hesitation. It also messes up some of my fastener plans, if I add the jack studs, such as the thru-bolting with 10” TimberLok’s that I’m using on those knee braces between the floor and each end wall.

Would you skip or add the jack studs under these “soffit” and “ridge” beams?

One advantage of adding them, additional cost and weight of 8 more 2x4x8 PT’s, is that things tend to get bumped around when operating a front-end loader in the tight quarters that makes up my wood lot. The jack studs would make everything more stout when I’m maneuvering a tractor and making huge piles of logs right next to these racks.

For zoning reasons, these need to be kept as portable structures, so we’re talking about essentially a pallet with a roof to keep the wood dry. This works out, in my case, to be cribs with a footprint of 8’ x 3’. Each will hold a cord of wood, and while technically mobile, they will be bolted together in a long row. There will be approximately 30 of these cribs.

Yes, I know the many potential disadvantages of this plan, but it has several advantages, and I’m willing to accept the trade-off. The question now is on framing.

Here is the rough sketch of the design:

Those 2x6 ridge beams, which run 8 feet from side to side at four locations are currently just attached to the four pairs of end wall studs with either four 3” deck screws or two 3” TimberLok fasteners. No jack studs, and I am beginning to wonder if I’ll regret this decision:

(Ignore the 1x2 strapping I’m using for temporary cross-bracing in this photo)

The roof is only 24 square feet, but we sometimes get up to 3 feet of heavy wet snow in a single shot, so snow load could be high. Yet, this thing is already stupid heavy (like 1000 lb.), which is part of my hesitation. It also messes up some of my fastener plans, if I add the jack studs, such as the thru-bolting with 10” TimberLok’s that I’m using on those knee braces between the floor and each end wall.

Would you skip or add the jack studs under these “soffit” and “ridge” beams?

One advantage of adding them, additional cost and weight of 8 more 2x4x8 PT’s, is that things tend to get bumped around when operating a front-end loader in the tight quarters that makes up my wood lot. The jack studs would make everything more stout when I’m maneuvering a tractor and making huge piles of logs right next to these racks.

Last edited by a moderator: