Hi all,

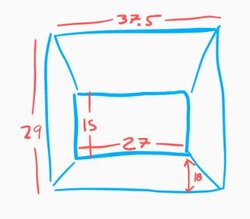

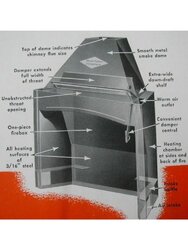

Im currently debating the best way to go about re-adding a fireplace to my house. At some point in its ownership the fireplace was drywalled in. I believe I have is a Heatform or heatilator. (https://www.hearth.com/talk/wiki/heatform/) perhaps someone with a better trained eye can tell.

I have removed 8" of drywall and stud around the opening of the fireplace as I have seen this referenced (between 6-8") in many insert manuals. My plan now is to replace what was there with cement board and metal studs and eventually face with thin brick.

I have a few concerns im looking for guidance on:

1) There is ~1.5" airgap between my metal firebox and the face of the wall. Is this a concern? If so how should it be handled?

2) There are cavities without brick on each side of the heatform. I understand now that these may be air intakes. Can these be left alone?

3) Does anyone have a recommendation for an insert can fit in this space? Most inserts ive looked at are too tall in the back as this slants aggressively. (Attached)

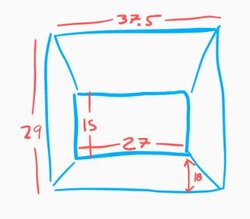

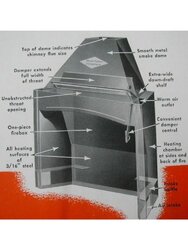

Im currently debating the best way to go about re-adding a fireplace to my house. At some point in its ownership the fireplace was drywalled in. I believe I have is a Heatform or heatilator. (https://www.hearth.com/talk/wiki/heatform/) perhaps someone with a better trained eye can tell.

I have removed 8" of drywall and stud around the opening of the fireplace as I have seen this referenced (between 6-8") in many insert manuals. My plan now is to replace what was there with cement board and metal studs and eventually face with thin brick.

I have a few concerns im looking for guidance on:

1) There is ~1.5" airgap between my metal firebox and the face of the wall. Is this a concern? If so how should it be handled?

2) There are cavities without brick on each side of the heatform. I understand now that these may be air intakes. Can these be left alone?

3) Does anyone have a recommendation for an insert can fit in this space? Most inserts ive looked at are too tall in the back as this slants aggressively. (Attached)